|

Accelerated Life-test Method for LED Drivers (2011)

An electrolytic capacitor.

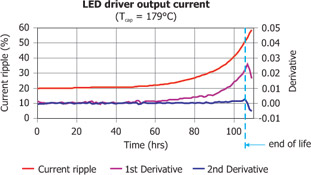

End of life criterion is based on the point at which the ripple current increases rapidly.

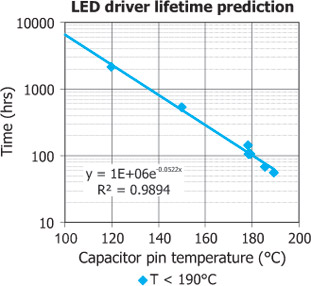

Lifetime prediction for LED driver as a function of capacitor temperature. By extrapolation, the predicted lifetime at 85°C ambient temperature (100°C at the capacitor’s pin temperature) is approximately 7,000 hours.

|

Much like a fluorescent lamp depends on a ballast to operate, LEDs require a driver. The LED driver converts unregulated AC voltage from an electrical outlet to DC constant current output. The LED driver is an integral part of any LED-based lighting system. While the life of an LED package may be long, the life of the driver may be much shorter, thus shortening the life of the entire system. Past studies have shown that the electrolytic capacitor used in switch-mode power supplies often has the shortest life of all components in the system and determines the electronic driver’s lifetime.

The LRC conducted a study to understand what factors influence the failure modes of standalone LED drivers, and to develop an accelerated test method to predict the useful life of an LED driver.

EXPERIMENT

The LRC experiment was designed to establish a relationship between the pin temperature of the electrolytic capacitor and the useful life of the LED driver. The pin temperature is indicative of the capacitor’s core temperature, a critical factor in the capacitor’s lifetime.

Sample commercial LED drivers were outfitted with a sealed container around the driver’s electrolytic capacitor, which acted as a localized oven. The temperature of this oven was kept constant through a temperature controller inside each case. A thermocouple attached to the pin measured the capacitor’s core temperature. The temperature values and driver output current parameters were recorded and analyzed using certain end-of-life criteria.

RESULTS

At different elevated temperatures, researchers monitored the capacitor’s output current ripple, which affects the input current to the LED, thus affecting the LED’s light output and efficacy. As the capacitor degrades, its capacitance decreases and its ESR, or equivalent series resistance (the sum of electrolytic resistance, dielectric loss, and electrode resistance) increases, leading to an increase in output current ripple. By establishing the sudden and rapid increase point of current ripple as the end-of-life criterion, it was possible to predict the lifetime of the electrolytic capacitor, and hence the life of the LED driver.

PUBLICATIONS

Han, L., and N. Narendran. 2011. An accelerated test method for predicting the useful life of an LED driver . IEEE Transactions on Power Electronics 26(8): 2249–2257.

Han, L., and N. Narendran. 2009. Developing an accelerated life test method for LED drivers. Ninth International Conference on Solid State Lighting, August 3-5, 2009, San Diego, Proceedings of SPIE 7422: 742209.

Full-text PDF

Project Summary Sheet

SPONSOR

NYSTAR (RPI Center for Future Energy Systems)

Alliance for Solid-State Illumination Systems and Technologies (ASSIST)

|