|

Estimating the Junction Temperature of AC LEDs (2011)

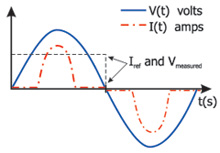

Zero-crossing point where the reference current is applied.

|

Light-emitting diodes (LEDs) operating on alternating current, known as AC LEDs, are gaining popularity in the LED industry, especially for lighting applications. Traditional direct current (DC) LEDs require an electronic driver to convert AC wall-plug power to DC operation, but newer AC LEDs eliminate the need and cost for a driver. Because LED life is influenced by heat at the chip’s p-n junction, predicting the junction temperature (Tj) is essential to accurately characterizing LED performance within a lighting system.

Extensive research has been conducted on ways to measure Tj in DC LEDs, but similar studies on AC LEDs have been limited. One AC LED study proposed using an active heat sink to recover the RMS current of the first half cycle to estimate Tj.* In the LRC’s study, researchers developed an alternative method of estimating AC LED junction temperature and thermal resistance.

ALTERNATIVE METHOD

The alternative method is based on an established method for DC LEDs, called potential (voltage) drop, to estimate Tj and calculate the LED’s thermal resistance. In the new method, a low reference current (0.1 mA) having a pulse width of less than 2 milliseconds is applied at the zero-crossing point of the AC LED current waveform, and the corresponding voltage across the device is measured. Then the correlation between the measured voltage and measured pin temperature is calibrated. Using this calibration curve and the average measured voltage, Tj and thermal resistance can be calculated. For validation, results were compared with the RMS current method.

RESULTS

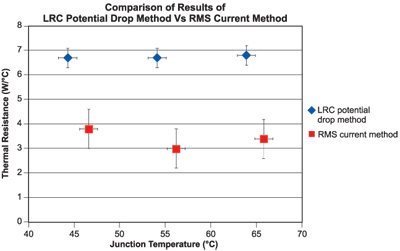

Because thermal resistance correlates to Tj, comparisons of thermal resistance between the two methods are shown. The thermal resistances for the same commercial AC LED are significantly different between the two methods. The following reasons may have contributed to this difference:

- • The RMS method claims that Tj rises 25% of the total rise within the first half cycle of the AC current waveform. This could introduce significant junction heating and error in the thermal resistance calculated by the RMS method. Further study is needed to ascertain the initial junction heating during the first half cycle to estimate the error it introduces.

- • Thermal resistance is a function of the material resistivity and geometry. The two methods use different thermal environments (static thermal environment vs. active cooling), resulting in measurement differences.

- • The RMS method relies on the accuracy of the instantaneous measurement of the current. A slight variation in this measurement will cause a greater change in the final thermal resistance calculation. The uncertainty of the thermal resistance with the potential drop method was 0.4°C/W, while the uncertainty of the RMS method was 0.8°C/W.

Comparison of thermal resistances of two different methods at different junction temperatures.

* Zong Y. et al. 2009. Practical method for measurement of AC-driven LEDs at a given junction temperature by using active heat sinks. Proc. SPIE 7422: 742208.

TECHNICAL REPORTS & PUBLICATIONS

Jayawardena, A., Y. Liu, and N. Narendran. 2013. Analysis of three different junction temperature estimations methods for AC LEDs. Solid-State Electronics 86: 11–16; doi: 10.1016/j.sse.2013.04.001

Jayawardena, A., Y. Liu, and N. Narendran. 2011. Methods for estimating junction temperature of AC LEDs. Eleventh International Conference on Solid State Lighting, San Diego, CA, August 22-25, 2011. Proceedings of SPIE 8123: 81230I .

Full-text PDF

Liu, Y., A. Jayawardena, T.R. Klein, and N. Narendran. 2010. Estimating the junction temperature of AC LEDs. Tenth International Conference on Solid State Lighting, August 1-5, 2010, San Diego, CA, Proceedings of SPIE 7784: 778409.

Full-text PDF

Liu, Y., T.R. Klein, and N. Narendran. 2009. A measurement method for estimating the average junction temperature of AC LEDs. White LEDs 2009: The Second International Conference on White LEDs and Solid State Lighting, December 13-16, 2009, Taipei, Taiwan, WB2-3.

Full-text PDF

Project Summary Sheet (2010)

SPONSOR

Federal Aviation Administration (FAA/05-C-AT-RPI Mod#12)

|