|

|

|

|

|

Register Now

This live, interactive course is designed for professionals from the lighting, 3D printing, and related industries to understand the possibilities of 3D printing for lighting and to learn more about each industry's needs and capabilities. Learn from LRC researchers and 3D printing experts who are members of LRC's ASSIST 3D Printing for Lighting Consortium, including HP, Stratasys, and Desktop Metal.

Industry leader Govi Rao discusses the importance of 3D printing to lighting and the LRC's education on this topic.

Additive manufacturing (AM), more commonly known as 3D printing, is poised to revolutionize the lighting industry. Indeed, the revolution has already begun with several manufacturers now offering 3D-printed lighting fixtures to the commercial market.

It is expected that 3D printing will offer many benefits in the manufacturing of components for lighting systems, including fabrication of cost-effective unique parts that cannot be made using traditional manufacturing methods and reduction of supply chain disruptions.

The Lighting Research Center (LRC) has been conducting research and development activities in the application of 3D printing to lighting since 2015. To share this knowledge and experience, the LRC is offering a five-week, interactive, online course on the application of 3D printing to the design, development, and manufacturing of lighting components and products.

Who should take the course?

Professionals from the lighting industry interested in learning more about the use of 3D printing in the design, development, and manufacturing of lighting components and products.

Professionals from the 3D printing industry interested in the application of 3D printing technology to lighting.

Anyone who wants to better understand the possibilities and impacts of 3D printing in lighting product lines, including:

- Equipment and materials manufacturers

- Product and innovation managers

- Industrial designers

- Engineers

- Product developers

- Research and development professionals

Course Objectives

At the conclusion of the course, attendees will be able to:

- Appraise the value of 3D printing for manufacturing lighting systems

- Understand the 3D printing process from design to manufacture and post-production of components as it applies to lighting systems

- Understand the performance requirements of electrical, mechanical, optical, and thermal components in lighting systems; and the needs of different lighting applications

- Compare the most common methods of 3D printing processes and technologies, and the pros and cons of each related to the fabrication of various lighting components

- Assess material, print parameters, and finishing requirements for lighting fixture components and systems

- Design a 3D-printed component for a lighting fixture and learn the steps involved to characterize and optimize the designed component

- Understand the process that goes into testing, evaluating, and quantifying the performance of 3D-printed lighting components

Course Certificate

Participants who successfully complete the course will be awarded a certificate from the Lighting Research Center including 15 continuing education units (CEUs).

Course Description and Schedule

The course will provide training in the application of 3D printing to the design, prototyping, and manufacturing of lighting system components, and give participants the knowledge and skills needed to begin applying this technology in their own companies.

There will be weekly (approximately 2.5-hour) live, interactive sessions hosted by course faculty via an internet-based conferencing system, as well as supplemental activities and assignments to be completed by course participants throughout the five-week course period. Industry leaders will join LRC faculty to present updates on the state-of-the-art of additive manufacturing technologies.

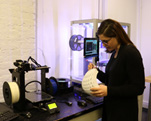

Course participants will work interactively with course faculty in live, remote laboratory sessions. Participants will also design components that will be additively manufactured at the LRC and returned to participants for evaluation as part of the course sessions.

The course will begin on July 9, 2025 and will run through August 6, 2025. Classes will meet on five Wednesdays from 11:30 AM to 1:30 PM US Eastern Time. A more detailed schedule of course activities, presentations, and assignments will be provided upon registration for the course.

An overview of course content is included below.

July 9, 2025 - Session 1: This session will begin with an introduction to the lighting and 3D printing industries, including an overview of 3D printing processes, their pros and cons, benefits compared to other manufacturing processes, and potential lighting applications for 3D printing. The session will also provide an overview of the size of the 3D printing market, trends, and growing applications. LRC researchers will share relevant case studies of the current best uses of 3D printing in the manufacture of lighting components and review best practices for 3D printing design. The session will end with a discussion of how 3D printing can support product innovation and differentiation..

July 16, 2025 - Session 2: Comparison of 3D printing processes and technologies, including an overview of the various types of 3D printing technologies and the pros and cons of each in terms of rate, quality, value engineering, and flexibility. The session will also cover availability of materials, material properties needed for lighting products and their certification, and the impact of printing parameters and post-processing on final product finish and lighting design targets. The selection of individual participantsí course projects will occur during this session. The project entails designing, 3D printing, and characterizing a specific light fixture component(s) or a complete fixture selected by the participant.

July 14-18, 2025 - Bonus Session: Join this optional, virtual session to learn and interact live with industry representatives from leading 3D printing original equipment and material manufacturers. Date and time to be finalized.

July 23, 2025 - Session 3: Discussion of optical component printing, including a review of the printing process for both transmissive and reflective optical components, as well as 3D printing design and fabrication parameter pitfalls, tips, and suggestions. The discussion will begin with an introduction to photometry and colorimetry terms, followed by an examination of the short- and long-term requirements of optical components for various lighting applications. This session will also include a live interactive lesson in which the course faculty will lead participants through the measurement and evaluation of 3D-printed optical components. This session will also include research results of short-term and long-term performance characterization of both transmissive and reflective components. The session will discuss 3D object creation with computer-aided design (CAD), including a review of slicing software programs and requirements for 3D printing of optical components. As part of this session, each participant will have to design an optical component as a take home assignment. The participants will share the CAD model(s) with the LRC. The LRC team will guide the design fabrication using selected 3D printing technologies and materials at 3D printing service vendors. The fabricated components will be either shipped to the LRC for characterization. .

July 30, 2025 - Session 4: This session will cover the design principles and 3D printing of heat sinks, including an overview of thermal management theory, analysis of the thermal performance of heat sink components, heat sink build orientation, print parameters, application orientation-related performance, and the effects of LED junction temperature on light output, color, and other factors. The presentations will cover the short-term and long-term impact of 3D-printed components under environmental stressors. This session will include an interactive lesson on junction temperature measurement. After this session, each participant will design a heat sink for an LED lighting product. Similar to the previous session, 3D object creation with computer-aided design (CAD), including a review of slicing software programs and requirements specific to thermal components, will be demonstrated and discussed. Participants will design the CAD models outside of class time and share the designs with the LRC. The LRC team will guide the participants in fabricating the designs using selected 3D printing technologies and materials at 3D printing service vendors. The fabricated components will be either shipped to the LRC for characterization. .

August 6, 2025 - Session 5: Discussion of the measurement and analysis of 3D-printed components sent to the LRC, provided the individual participant has agreed to share the designs and information on the characterizations in this open session. This session will include a combination of live session on sample photometry and thermal measurements, light output, beam and color quality evaluations, and LED junction temperature calculation and analysis as well as sharing of results from characterizations that were conducted outside class times at the LRC. The class will end with a course discussion, review, and a question-and-answer session. For participants who wish the characterization information to be confidential, a separate one-hour one-on-one session with the LRC researchers during the week of July 21-25 by prior appointment can be requested.

Cost and Registration

The cost of this five-week course is $1,800. Registration availability is limited. You can register at the link below.

Register Now

Faculty

Indika Perera, PhD — Dr. Perera is a research scientist at the LRC. His research interests include thermodynamics, heat transfer, material characterization, and additive manufacturing of solid-state lighting components and systems. Dr. Perera‚Äôs expertise is in the thermal management of LED lighting systems and of phosphor and down conversion materials used in LED packages, including the development of a mathematical model for predicting the temperature distribution in an LED phosphor layer. His current research includes investigations of the thermal properties of 3D-printed heat sinks and components for use in LED lighting systems, characterizations of composite materials used in additive manufacturing, and analysis of theoretical models for predicting the thermal conductivity of 3D-printed components.

N. Narendran, PhD — Dr. Narendran is a professor and director of research at the LRC. He is well known for his pioneering research in the field of solid-state lighting, including LED performance improvement through novel packaging, development of accelerated life-testing methods, and the use of LEDs in high-value lighting applications. His current research focuses on 3D printing for lighting, specifically investigations of the functional properties of materials to produce components for lighting fixtures, including mechanical, thermal, optical, and electrical subcomponents. Additionally, Dr. Narendran organizes the Additive Manufacturing for Lighting Consortium at the LRC, which brings together key stakeholders from the 3D printing and lighting industries to work collaboratively to revolutionize lighting manufacturing. Through these activities, Dr. Narendran and his research group are leading the lighting industry transformation to supply on-site, on-time delivery of cost-effective lighting components and fixtures, and thus changing the current lighting practice. Dr. Narendran has authored more than 130 articles in archival journals and proceedings and holds over 50 patents. He is a Fellow of the Illuminating Engineering Society of North America and a member of the committee on the assessment of solid-state lighting for the National Research Council of the National Academies.

Jean Paul Freyssinier, MS — Professor Freyssinier is a senior research scientist and adjunct assistant professor at the LRC. His research includes solid-state lighting, LED performance, technology transfer, energy-efficient lighting design, photometry, the spectral effects of lighting, and education. Since 2000, he has been involved in lighting technology research, development, and evaluation at the LRC. His previous experience includes working as principal of design at a full-service architectural lighting and automation design firm and as project manager at an energy management firm. He has taught in the LRC's graduate education program for the past 15 years and lectures frequently at conferences and seminars. He is the author of more than 35 scientific and technical articles related to energy efficiency, photometry, improved LED performance, and field applications, and co-author of six patents on LED remote phosphor technology.

For more information

Please contact LRC's Director of Research, N. Narendran, at narenn2@rpi.edu to learn more.