About Us

An objective, international resource for LED lighting research since 2001

Now expanding research toward greater benefits for lighting with 3D printing

The Solid-State Lighting Program at Rensselaer's Lighting Research Center supports the lighting industry through research that shows the value of LED lighting in built environments and educational activities that teach how to optimize LED lighting systems with new capabilities while maintaining reliable system performance.

Solid-state lighting (SSL) has evolved to a point where the light-emitting diode (LED) is now the preferred light source for many lighting applications. However, price erosion has been a challenge for lighting fixture manufacturers. The production of LED lighting products overseas has affected the quality of both products and the lighted space, as well as impacting the local economy. 3D printing holds promise for solving this issue.

The 3D Printing for Lighting Program at the LRC introduces the possibilities of 3D printing for lighting and how it can benefit the different collaborating industries. The goals of the LRC's new program, established in 2019, are to advance LED lighting system manufacturing using 3D printing technologies, to overcome barriers, and to show benefits to each industry.

The program’s multidisciplinary staff is focusing its research and educational efforts in the following areas:

– investigation of the thermal, optical, and mechanical characteristics of lighting systems and components

– identification of suitable 3D printing machines and materials needed to manufacture high-quality components that can improve performance

– market transformation activities including field demonstrations, education, and standards development through industry collaboration

The Benefits of 3D Printing for Lighting

– 3D printing allows for lower cost, higher quality custom lighting fixtures and components, printed on-site and on-demand.

– 3D-printed lighting systems can reduce the carbon footprint and improve the sustainability of LED lighting by not making and shipping fixtures halfway across the globe.

–

3D printing of lighting systems can bring manufacturing back to the local area and create employment opportunities to improve the local economy.

|

At the LRC, we are working together with a newly formed consortium, the ASSIST 3D Printing for Lighting Consortium, to transform the industry toward providing custom lighting fixtures, manufactured on-site and on-demand, that will elevate the appearance, value, and experience of the built environment. The consortium's aim is to make 3D printing a viable option for the lighting, building, and construction industries, and other allied lighting industries.

The LEDs & 3D Printing Program is led by LRC Director of Research N. Narendran, Ph.D., who also oversees the graduate and professional education programs held at the LRC.

Use the links at left to learn more about the LRC's research and advocacy work in LED lighting and 3D printing.

What is Solid-State Lighting? What is Solid-State Lighting?

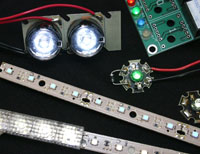

Lighting applications that use LEDs, organic light-emitting diodes (OLEDs), or light-emitting polymers are commonly referred to as solid-state lighting. Unlike incandescent or fluorescent lamps, which create light with filaments and gases encased in a glass bulb, solid-state lighting consists of semiconductors that convert electricity into light. LEDs have been around for more than 50 years but until the early 2000s were used only in electronic devices as indicator lamps.

Technological developments allowed LEDs to be used first in signal devices, like traffic lights and exit signs, then in some limited illumination applications, such as flashlights, and today for most general illumination applications, from homes to commercial spaces to outdoor lighting. Since 2001, the Lighting Research Center has been instrumental in conducting research to make this transformation happen.

Why Solid-State Lighting?

Solid-state lighting is used in a variety of lighting applications because it offers many benefits, including long life, energy savings, and better quality light output. They are also considered durable, intrinsically safe, and ideal for smaller, flexible light fixtures.

|

| |

What is 3D Printing for Lighting?

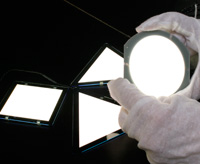

Additive manufacturing, also known as 3D printing, allows objects of almost any shape or geometry to be manufactured from digital model data. One value of 3D printing for SSL is the ability to design custom lighting fixtures that match the architectural features of a building and then “print” or manufacture them on-site for quick installation. 3D printing also can be beneficially utilized at the fixture component level. With 3D printing of fixtures, heat sinks can be designed to be part of the fixture envelope rather than attached afterwards, which would reduce the fixture’s bulk size and cost and improve its attractiveness. |

|